Cleveland Cascades Complete Chute Extensions and Commissioning for Christmas Island Phosphates

Cleveland Cascades Engineers recently visited Christmas Island, (Australia) to support with the installation of the North Arm Cascade Chute and extend the South Arm Cascade Chute on behalf of Christmas Island Phosphates.

The South arm has been extended from the original installation to meet with the needs of the vessels being loaded. The North Arm has now been fully installed and commissioned and both Cascade Chutes are operating loading Phosphates at 800 to 1000 tons per hour.

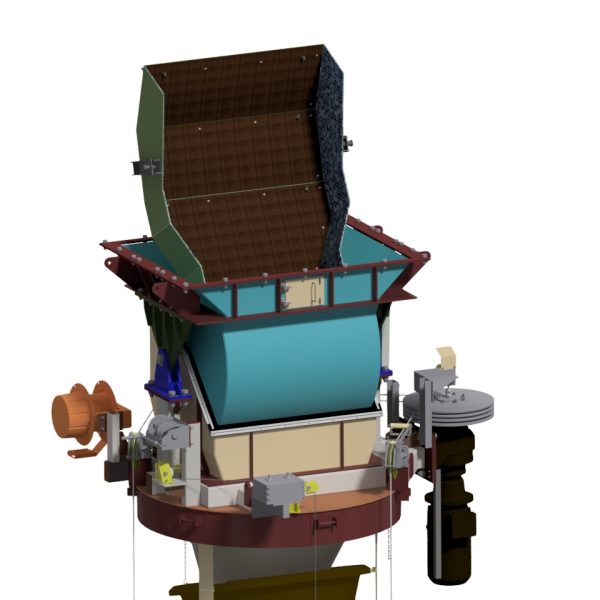

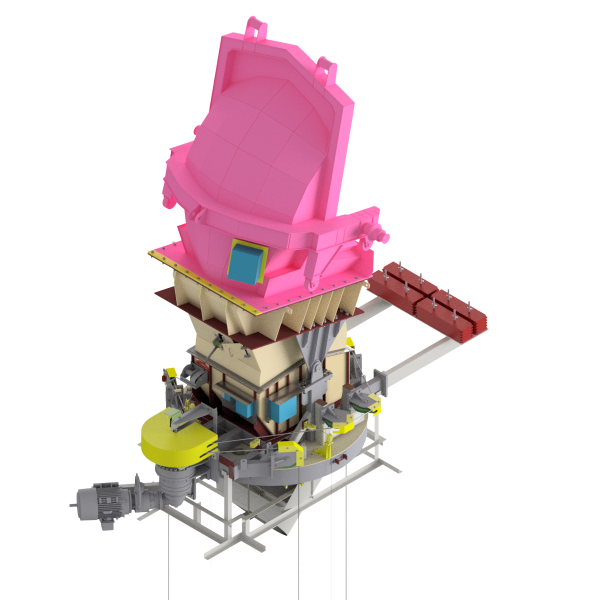

The pair of 1100 size Cascade Chutes are designed for dual use for simultaneous loading and are 26 meters in length with a capability to retract to 7.07m, The cones are lined with 6mm UHMWPE for abrasion protection. Both Chutes are mounted from a fixed head chute fitted to a shuttling boom.

Each system is fitted with a Speed Reducer (Picture below) for further slowing of material prior to exit of the chute thus reducing dust and material degradation, and a Resitain Valve which prevents the evacuation of material whilst the chute is being re-positioned and loading is not underway.

Following installation evaluation and cold running trials both chutes were hot commissioned during loading of a vessel as can be seen in the video’s below:

CC554 Loading Phosphates at Approximately 800tph

CC555 LOading Phosphates at Approxinately 800tph

The Gallery below shows the ship loader, cascade chutes and vessel during loading and CC554 in position for maintenance.

- CC554 South Arm Ship Loader

- CC554 & CC555 Loading Phosphates

- CC554 South Arm Loading Phosphates

- CC555 North Arm Loading Phosphates

- CC555 North Arm Loading Phophates

- CC555

- CC555 North Arm Loading with Shroud Down

- CC554 Cascade chute in Maintenance position

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260