Free Fall Chutes

Cleveland Cascades offer chutes suitable for effective use in a vast range of different applications and our product range is not confined solely to Cascade, controlled flow technology chutes.

In applications where the weight carrying capacity of the loading structure is limited and where dust control, material degradation and material separation are not major factors, Free Fall chutes can be a cost effective solution and our product range includes bespoke solutions utilising Free Fall Chute technology.

As with all our products, the central core of our offering is a bespoke engineered solution to meet the precise requirements of the application. Each Free Fall chute is designed and manufactured to the same rigorous and robust standards as our Cascade chutes. We offer two types of Free Fall systems; The FFC (Cone) system and the FFT (Tubular) system.

Materials handled

- Alumina

- Animal feed

- Bauxite

- Bentonite

- Biomass

- Cement clinker

- Cereals

- Coal

- Copper Concentrate

- Dolomite

- Finished cement

- Fly ash

- Grain

- Gypsum

- Iron Ore

- Kaoline

- Limestone

- Olivine sand

- Pelletized materials

- Perlite

- Petroleum coke

- Phosphate

- Polyhalite

- Potash

- Salt

- Soda Ash

- Sulphur

- Urea

- Zinc

C Series

The C Series, Vertical Cone System

The Free Fall C system utilises a series of cones and the modular design used in a Cascade system. But instead of being inclined, the cones are vertically suspended from chains or strops, allowing the material to fall vertically to the pile.

Externally an outer shroud allows for the air displaced during loading to be captured and maintained. If the application is sensitive to dust emissions, the shroud allows for a dust extraction system to be fitted, to ensure dust free loading.

Just like the Cascade systems, the materials used in the construction of our Free Fall Chutes are bespoke to the application and any special requirements, such as ATEX / NEMA / CSA can be included in the design. The well-engineered design and robust construction of the chutes are manufactured to ISO9001 quality standard and give many years of trouble-free service.

Tanker & Vehicle Loader

Tanker Loading Chutes

The TL Series, Vertical Cone System

Cleveland Cascades Tanker Loading Chutes utilise the same vertical cone design, used in the C Series Free Fall Chute. The Free Fall principle is highly effective when loading in to the enclosed space of a Tanker. The system is fitted with a completely sealed closure cone which connects to the tanker inlet.

A weatherproof shroud is fitted over vertical cones to ensure dust cannot escape into the environment, and also to allow for the effective extraction of dust-laden air if required. The shroud is built to the same proven, robust design used on our Cascade chutes.

Once loading is completed through the chute, the closure cone delays lifting for a short period of time to ensure that any excess dust held up in the system, has settled.

Vehicle Loading Chutes – Cascade or Free Fall

Open Vehicle Loading Chutes

The loading of dry bulk material into open vehicles, whether road or rail, is an area of the industry which is susceptible to problems of dust creation, material degradation and separation as well as over-filling and spillages. Cleveland Cascade loading chutes can provide an effective high performance solution to meet all of these challenges.

Depending on the application and the material being handled we can offer our Cascade, controlled flow technology chute or our Free Fall vertical cone system. The cone material supplied can be agreed during the quotation process, but might include wear resistant liners and protection against corrosive materials such as Urea or Sulphur.

Case Studies & References

We have built up an impressive population of Free Fall chutes in loading installations all around the world, handling a wide range of dry bulk materials.

Our Free Fall Customers include:

- Castle Cement

- Cargotec Sweden

- Cememti Rossi

- Conoco

- CUCPSA

- Dublin Port Company

- Duro Felguera S.A

- EMS Tech Inc.

- Fluor S.A – Alcoa

- Forth Ports Plc

- IMASA

- Irish Cement Ltd.

- MIE Malaysia

- NK Technologija

- Norsk Hydro

- Odebrecht

- PHB Weserhutte

- Redland Aggregates Ltd

- Rugby Cement

- Sherburn Group

- Tarmac

- Titan Cement UK

- TECHINT

- Telestack

- Tenova

- ThyssenKrupp

- WBB Minerals

And many more. Please see our Customer Reference List

Free Fall Case Studies

- Irish Cement (PDF document)

- Telestack (PDF document)

- 762 Odebrecht (PDF document)

- Titan Cement (PDF document)

Press Articles

T Series

The T Series, Telescopic Tube System

The Cleveland Cascades T Series Free Fall Chute comprises of a series of telescoping concentric tubes. It is supported at the head chute interface point and can extend and retract to suit the length required for each loading job.

Unlike the modular Free Fall C Series, the Chute remains rigid and is ideally suited to applications which require Trimming Spouts or Jet Slinger devices.

The T Series incorporates a scraper/brush cleaning system at the head of each tube, which

is beneficial for particularly sticky materials, where periodic cleaning is an issue.

The system can be manufactured from a range different steel grades, depending on the dry bulk it handles. It can also be fitted with wear resistant and low friction replaceable liners for sticky or corrosive products.

At the base of the T system there is an option to fit a standard skirted outlet or a rotating Trimmer device for accurate loading and finishing. There is also the option for a Jet Slinger device, which throws the material much further in to the hold than a conventional trimmer.

The Free Fall chutes are not designed to specifically control dust emissions or prevent degradation, but they do eliminate the effects of side winds and also prevent uncontrolled dispersion that can occur in ship loading and storage applications. The T System is particularly effective in handling sticky materials which have a relatively high moisture content such as metal ores and mineral concentrates.

Guide rails are fitted to the tubes to prevent them from twisting and distorting during extension & retraction and also whilst using a Trimmer Spout or Jet Slinger outlet.

Options

Trimming Spouts (T System only)

Free Fall T Systems can be specified fitted with a rotating Trimmer Spout. This enables accurate positioning of the load within the ships hold and helps ensure maximum utilisation of the hold space available.

The Trimmer Spouts can be supplied built from various grades of steel and lined with abrasion resistant liners for extended operating life.

Outlet Dust Extraction Units (C System only)

In applications which require both a relatively lightweight chute and where dust pollution needs to be controlled, Free Fall C series chute fitted with Dust Extraction Units can be an effective solution.

The extraction unit is carrier-mounted at the base of the Chute (Outlet). This is the optimum position for dust extraction, right at the source of the dust creation. The rate of dust extraction and the specification of the extraction unit can be agreed during the enquiry phase to meet the requirements of the job.

Head Chute Dust Extraction System (C System only)

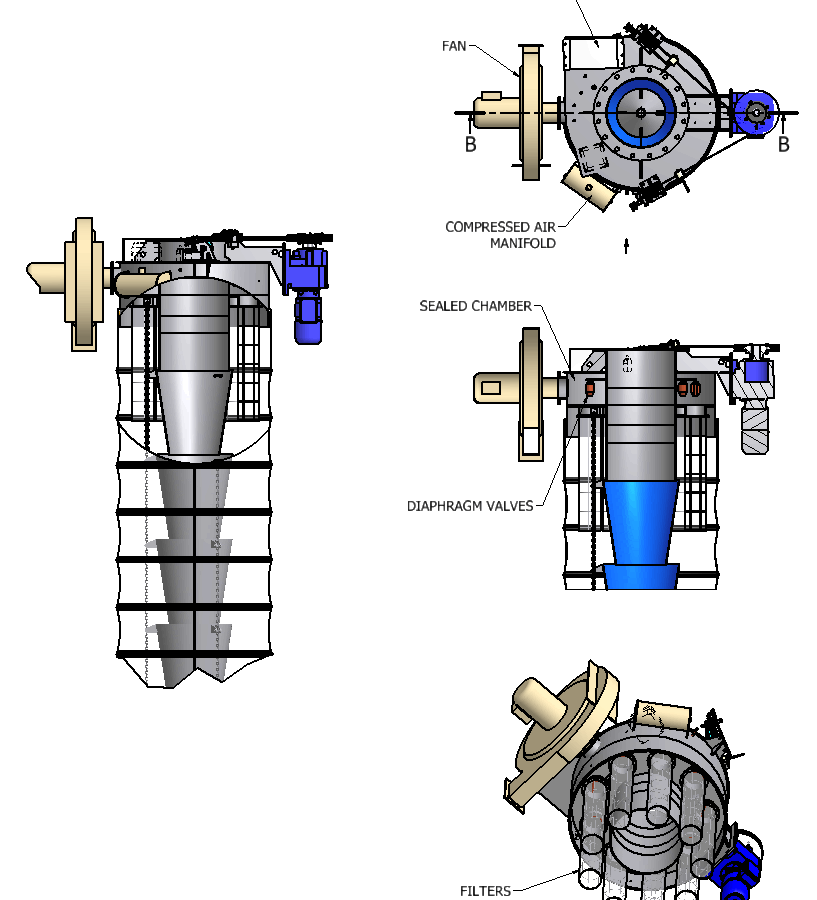

The system has been developed in conjunction with Donaldson Filtration Systems, the leading global specialist in Filtration Technology.

It is integrated in to the head chute and comprises a fan motor, compressed air manifold along with up to nine filters & diaphragm valves which are controlled via an Integrated Pulse Controller (IPC).

The system operates by the 0.55Kw motor providing the extraction through each of the filters inside the chute. The manifold allows each filter to clean itself intermittently with a burst of compressed air. Whilst one fan is performing a pulse-clean, the remaining eight are operating so that performance is never compromised. The extracted dust is taken away through the fan, or dropped back through the chute following each pulse-clean, to ensure a loading process with minimised dust emissions.

It can be used in various loading applications where dust control devices are not already installed to the on-site loading system, such as Open Vehicle & Tanker Loading. It is fitted to Cleveland Cascades Free Fall Cone chute systems and can be specified to meet various international standards such as IP65 as well as for use in areas with potential explosion risk, to ATEX standard.

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260