Cleveland Cascades Coal Loading Focus

Cleveland Cascades have supplied over 30 systems dedicated for loading coal products. These systems have been for, vehicle, stockpile, transfer chute and ship loading purposes. These have been our Cascade and Free fall systems dependent upon the application.

The majority of these have been supplied across Europe and South America with the remainder spanning across Africa, Asia and Australia.

Some examples of Cleveland Cascades Systems loading Coal are:

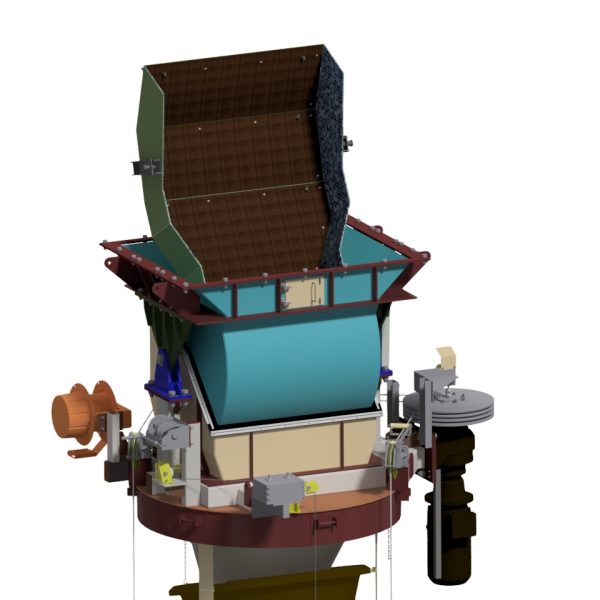

CC711

CC711 is specified for loading coal in Colombia, South America. This system was supplied in 2012 and has an extended length of 15.5m from interface to trimmer outlet with a retracted length of 6.3m.

Cleveland Cascades Ltd 1300 sized cones are used to meet the customers’ requirement of 1000tph throughput. This translates to a required volumetric loading capacity of 1176 m3/hr for the given density of the coal (0.8t/m3). The 1300 sized cones have capacity for up to 1450 m3/hr leaving room for any material surges which could occur during loading. (Image 1 & 2)

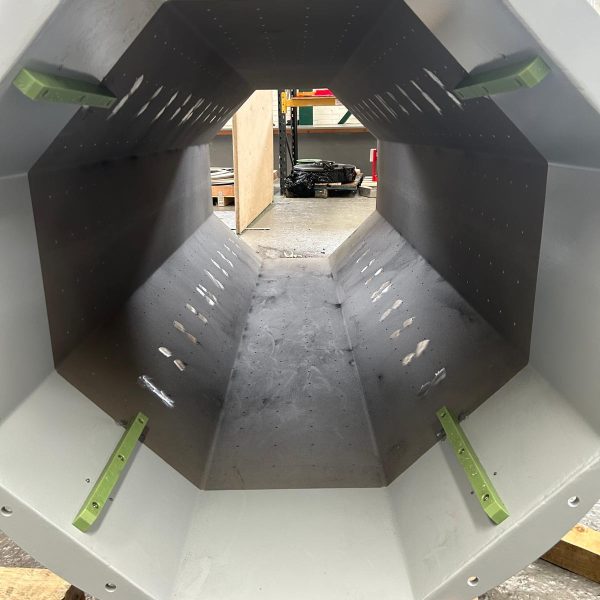

This system is fitted with a rotating trimmer outlet. Employing the use of a rotating trimmer outlet allows the material to reach the corners of a vessel when loading meaning all of the available space is utilised more efficiently. A typical trimmer assembly can be seen in Image 7. These units are supplied for use with many applications and can be lined with various grade liners for abrasion resistance.

FFT843

For this project a Cleveland Cascades Freefall Telescopic system was supplied in 2015 to the Port of Riga in Latvia designed with the intent for loading coal. The four telescopic tubes allow the system to reach an extended length of 12m from interface to trimmer outlet and provide enough travel to retract the system to be 7.6m long. The system can be seen installed awaiting loading in image 5.

Each Freefall Telescopic system is designed around the customers’ requirements. On this occasion, the maximum particle size for the coal was stated as 100mm with required nominal and surge throughputs of 2000tph and 2200tph respectively. This allows Cleveland Cascades engineers to create bespoke head chute and tube designs in order to reduce the risk of blockages occurring whilst loading operations are carried out.

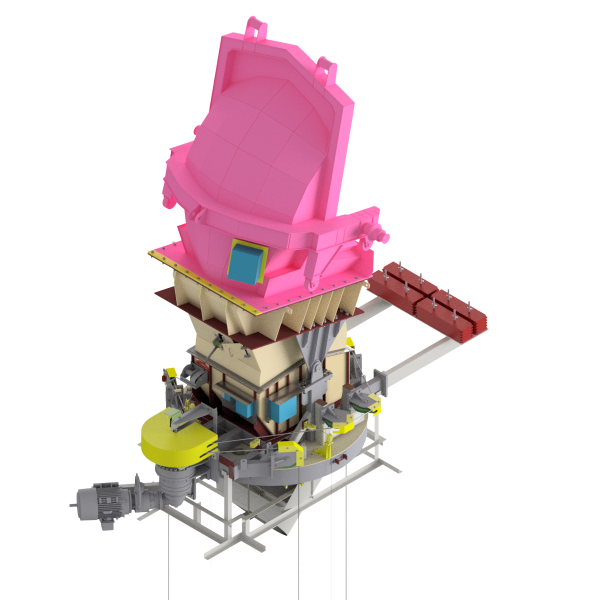

CC848

One of Cleveland Cascades coal loading systems supplied in 2016 to Colombia, South America. The extended length of the system is 23.8m long and can retract to a length of 6.1m. (Images 3 & 4)

Due to the lump size expected to travel through the system paired with the required throughput, 1500 sized cones were supplied in order to promote mass material flow and reduce product degradation.

Material detection probes are used to provide automation for raising the system as product is loaded. At the outlet of the system a skirted outlet was supplied, the main advantage of using a skirt is that it allows for dust suppression by maintaining contact with the material pile as the system retracts during loading. This system can be seen loading with the shroud down during initial load trials in Image 5.

The system can be seen loading coal during hot commissioning in the footage below:

- Image 1 CC711 Extended

- Image 2 CC711 Loading Coal

- Image 3 CC848 Chute and Ship Loader

- Image 4 CC848 Installed with Shroud down

- Image 5 CC848 Loading Coal

- Image 6 FFT843

- Image 7 – Standard Trimming Spoon Assembly

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260