Huelva FFT System – Assembly and lining underway at Cleveland Cascades

Our CC1001 Free fall Tube system is now at the lining and assembly stage in our workshop in Teesside.

The system is to be delivered to our customer for a project in Huelva, Spain for loading Copper concentrate at up to 1800 t/hr from a luffing Boom Shiploader.

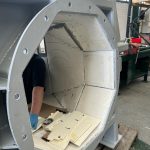

Below, the painted steel tubes can be seen in the workshop where the lining process is underway. Each of the tubes running faces are being lined with sintered alumina ceramic tiles. This is a manual process that requires time and skill to ensure a professional finish. Our trained workshop technicians are working hard with the lining process on the tubes presently.

Once the installation is completed, the tiles are then cleaned and prepared for curing which takes approximately 30 days.

As well as the tubes sections, the head chute and trimmer running faces are also being lined during this process.

In the gallery below we can see the steelwork for the anti collision bumper arrangement awaiting installation once the tubes are assembled.

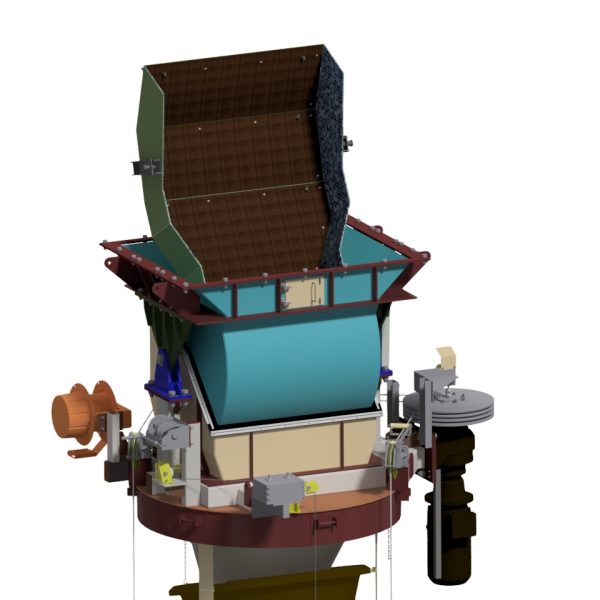

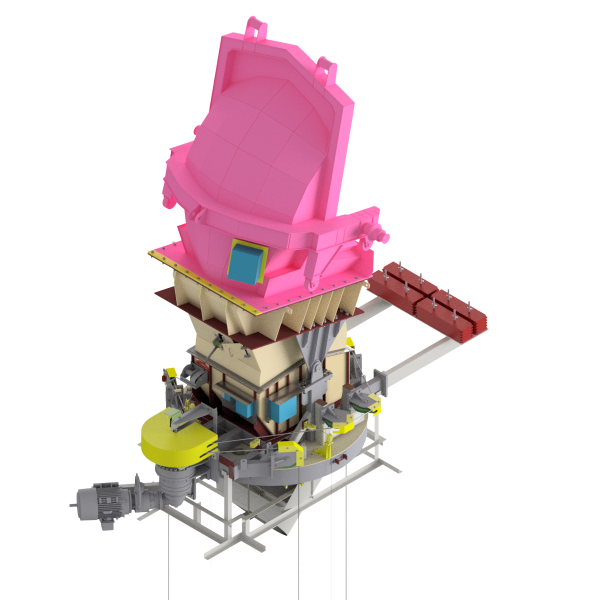

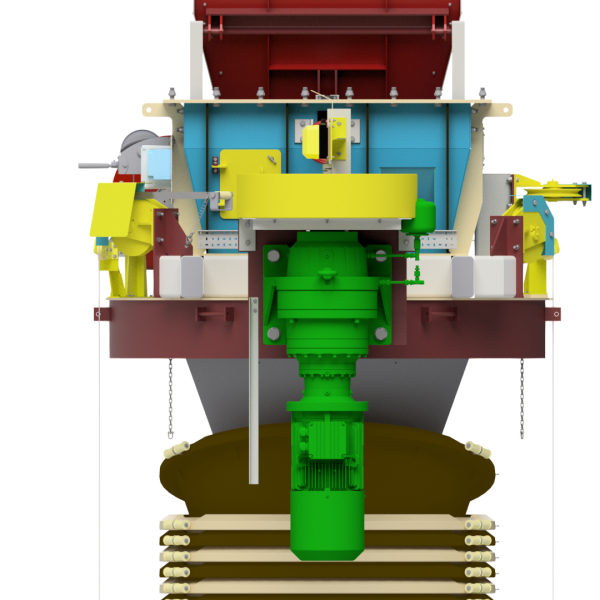

The full system can be seen in the design models below.

If you have a project that requires a loading solution such as out FFT system featured here or one of our cascade systems please reach out to us to discuss at enquires@clevelandcascades.co.uk

- FFT1001 with Trimmer Outlet

- FFT1001 Extended

- FFT1001 Head Chute

- FFT1001 Retracted

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260