Cleveland Cascade Chute Commissioned in Brazil

Last Month, our onsite engineers have overseen the commissioning of one of our latest Cascade chutes in Brazil. The system was loading Corn at 2000 metric tonnes per hour and will also go on to be used for loading Soy Meal, Soy Beans and Grain as well as Corn on a regular basis.

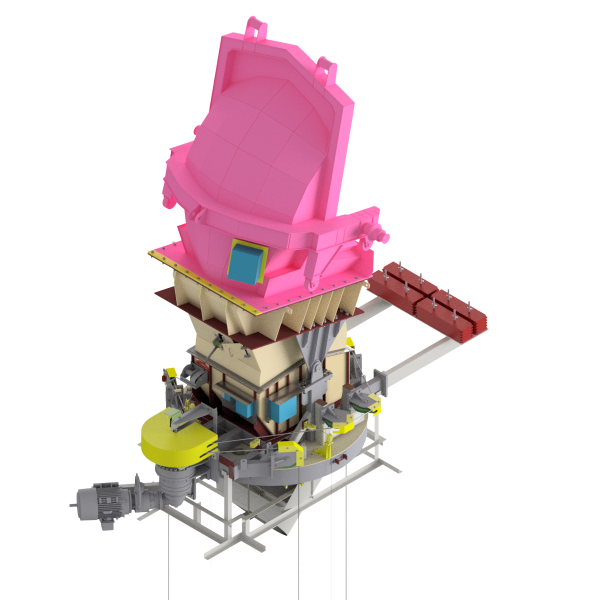

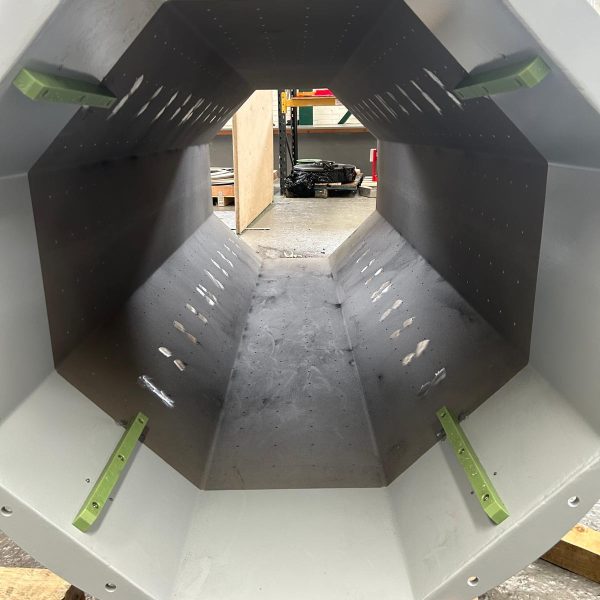

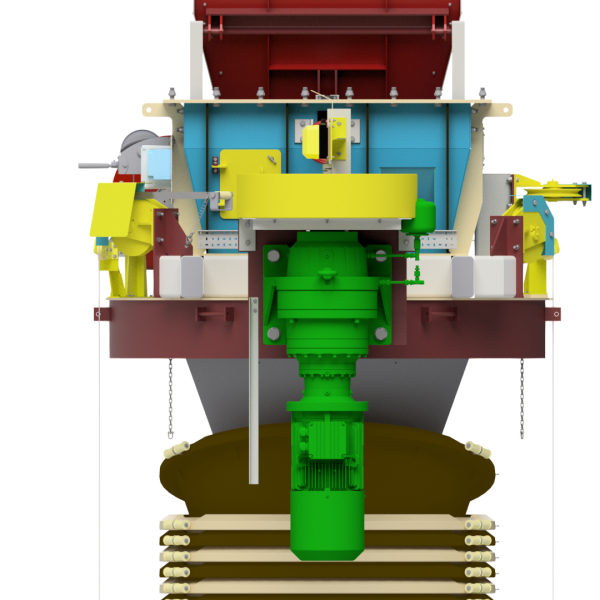

The Cascade chute is our 1900 sized system, with a maximum capacity of 4,500 cubic meters per hour of bulk materials loading. The chute provided is a total of 25 meters long, including a pivoting style head chute interface which works with the clients luffing ship loader boom in order to be able to load at various boom positions as well as stow at a parked angle of 70° when not in use or moving between vessel holds.

At the base of the Cascade chute, a skirt outlet is used for the most effective method of dust free pile forming. During loading, the Ship Loader is free to move, using its travel and boom shuttle functions in order to fill vessel hatches completely, with a continuous loading process.

The Cascade chute also has the option of using a rotating trimmer spout, or spoon, as an alternative outlet at the chutes base for vessel loading. Trimmer spoons are used when accurate loading is required under hatch covers to achieve complete hatch fill levels.

The picture gallery below shows the installed chute, and some images captured during loading.

It’s clear to see in this case, that the Cascade chute is working effectively, as designed in order to load the material at a low speed, yet high volume – mass flow. The material control achieved results in a soft, and smooth delivery of material from the chute into the vessel, and pile forming can occur without creating dust emissions, or degrading the material. This applies to Corn and the other agri-bulk products to be loaded here in Brazil, but the same principle and results can be applied to all free flowing bulk products, from fine powders like Alumina to granular and pellet products and even lump products like Coal and Coke.

This Cascade chute is the first of 2 systems which will be installed on this particular terminal in Brazil, the second installation and commissioning is planned for 2018 and our client can look forward to the same great results with that system. The video below demonstrates these results and more videos can be found on our YouTube channel of this particular chute and others.

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260