Cleveland Cascades Ltd complete on site training for Customer in Tabasco, Mexico

The services of our team of commissioning engineers were recently required in Tabasco, Mexico.

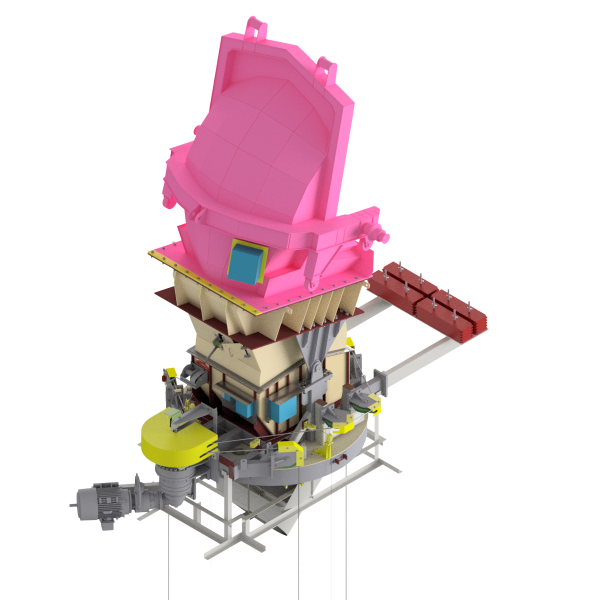

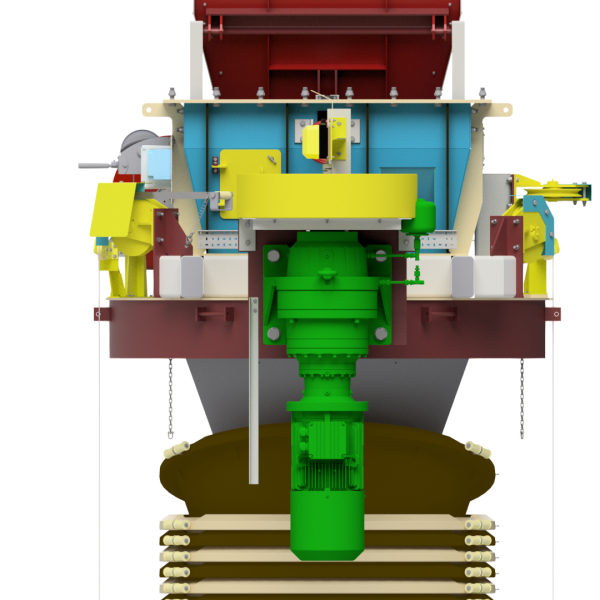

Three Cleveland Cascades chutes are currently being installed there. One is a 900 sized system and the other two are our 1100 size, all of which are to be used for vehicle loading. The systems are capable of handling contracted rates of up to 450tph and 880tph respectively as per the client’s requirements. Pet coke is the material which is to be handled by the systems.

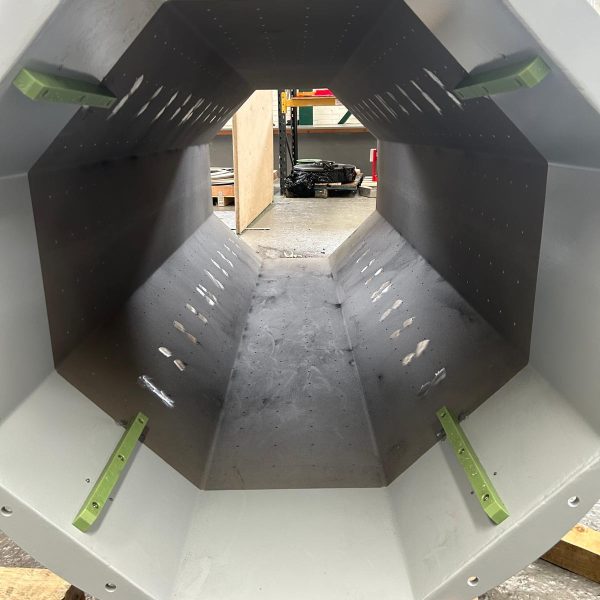

To combat the abrasive properties of the Pet Coke material which is stated to have particle sizing up to 100mm, each system employs the use of GRP cones with a ceramic tile liner. The abrasion resistant wear liner installed within the cones will ensure that these critical components of the system have a long service life before requiring replacement.

The cascade chutes are fitted with a comprehensive suite of electrical components for safe operation and control, including automated chute control whilst loading each material pile and providing signalling for any potential blockages. The safety systems provide feedback to the control system for the loaders with safety limits being interlocked with the conveyor system feeding the chute.

Our engineers conducted a series of training presentations passing on their knowledge of the systems to personnel on site who will operate the chutes. This will enable them to better understand system optimisation and how to rectify any issues that may arise during loading operations. A key focal point during the training sessions was planned preventative maintenance where critical spare parts were identified that should be held on site in the event that immediate replacement is required. The training included information on the maintenance procedures, functions of the various system components (both mechanical and electrical) and how to keep each system running optimally.

The engineers site visit afforded the opportunity to assess the condition and witness the installation progression of the systems. This identified missing critical parts of the system that are necessary for the system to operate safely and effectively. Being present on site ensures that the systems installation and setup can be verified by a trained Cleveland Cascades commissioning engineer yielding the best possible results for our clients.

After sales support is of utmost importance at Cleveland Cascades and we are proud to be able to offer our services for the life of the chutes. Whether this be site services, commissioning, training, or providing any spare parts that are requested.

Please don’t hesitate to contact us on the below email address if you have an enquiry for a new system or require assistance with an existing installation;

enquiries@clevelandcascades.co.uk

- CC974/5 Extended

- CC974/5 Shroud

- CC974/5 HC

- CC974/5 Carrier w/ Cones

- CC973 HC

- CC973 Extended

- CC973 Carrier w/ Cones

- Installation Progression on site

- Installation Progression on site

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260