Cleveland Cascades Ltd to Supply a Soda Ash Loading System to the Netherlands

Cleveland Cascade Ltd have secured yet another soda ash bulk material handling project.

The loading system which is currently in production will be installed to a rail mounted ship loader situated in The Netherlands.

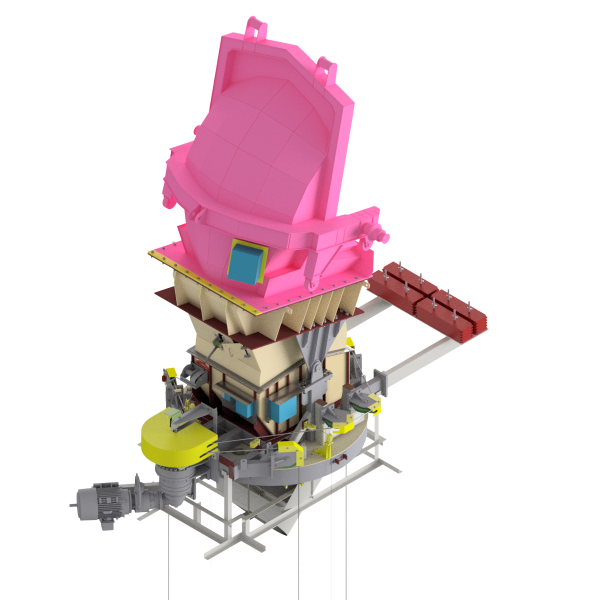

Measuring from the interface of the loading chute to the base of the skirted outlet, the system is capable of extending to 26.0m long. Utilising the head chute mounted winch hoist system, it is possible to achieve a retracted operational length of 6.0m, this can be further reduced to 5.7m when the system is non-operational.

Taking into account the required loading capacity, a 1300 sized system is specified which will allow for volumetric loading rates of up to 1,400m³/hr.

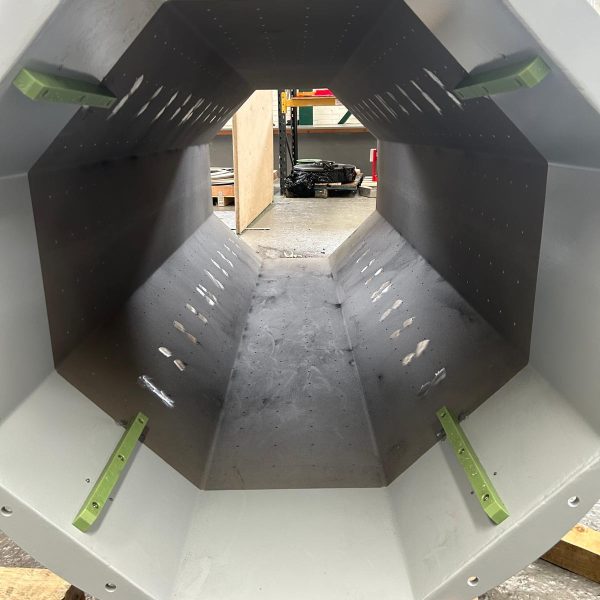

The in-house manufactured GRP cones are lined with UHMW PE wear liners which have a low coefficient of friction allowing the bulk material to pass freely through the system. This aids in promoting mass flow, a stream of material moving as a single mass as product is delivered through the cones ensuring that fugitive dust emissions are kept to a minimum during loading operations.

Also included in the supply is a full suite of electrical components for system safety and automation which is to be integrated with the ship loader PLC control system.

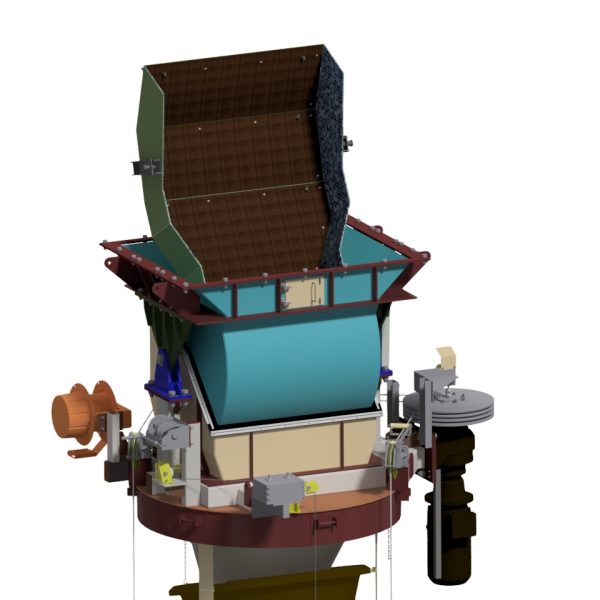

Some rendered images of the finalised CAD model can be seen in the gallery below.

If you have an enquiry relating to bulk material handling, be it for a new or existing Cascade, Free Fall Telescopic or Free Fall Cone system, then please contact us on the below email:

Enquiries@clevelandcascades.co.uk

- CC996

- CC996 Head Chute

- CC996 Retracted

- CC996 Extended

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260