Cleveland Cascades Site Service Support in Demopolis, AL, USA

Commissioning engineers from Cleveland Cascades Ltd. were recently deployed to assist our customer located in Demopolis, AL, USA. The objective of the site services was to aid with the installation of a previously supplied spares package following recommendations from a past trip to site, also, the system would be re-commissioned to achieve optimal performance.

The contracted services were broken down into three phases; system breakdown with spares installation, system rebuild and finally commissioning checks.

Phase 1 – System Breakdown & Spares Installation

This consisted of the commissioning engineers overseeing the system being removed from the ship loader and separated into its core components. Each of these were then placed in a maintenance area allowing for safe and easy access for any works to be carried out.

The spares to be installed consisted of some wearing and some critical items, highlighted from a previous inspection and flagged for replacement.

It’s important that checks are carried out in line with recommendations provided by Cleveland Cascades and that a planned preventative maintenance schedule is in place which features the loading system.

Phase 2 – Rebuilding of the System

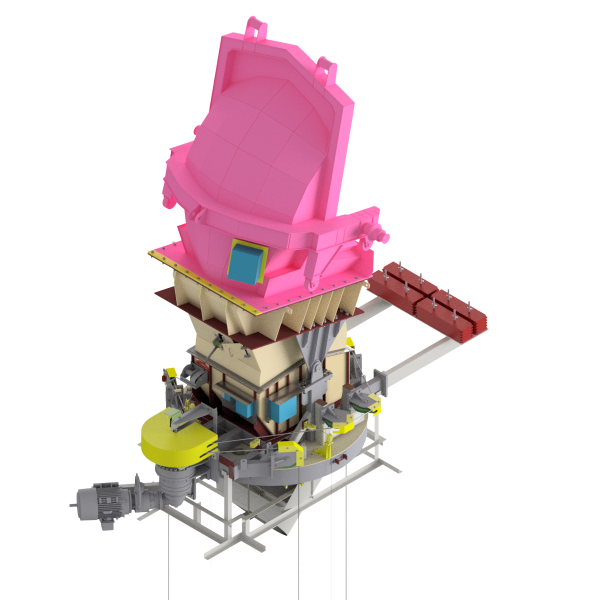

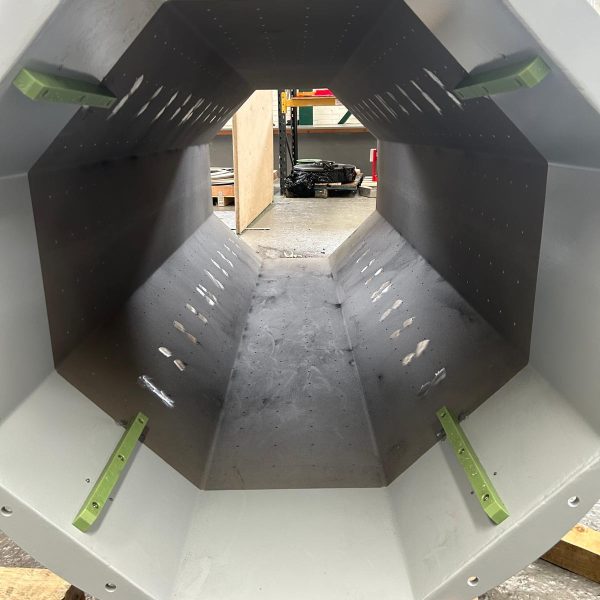

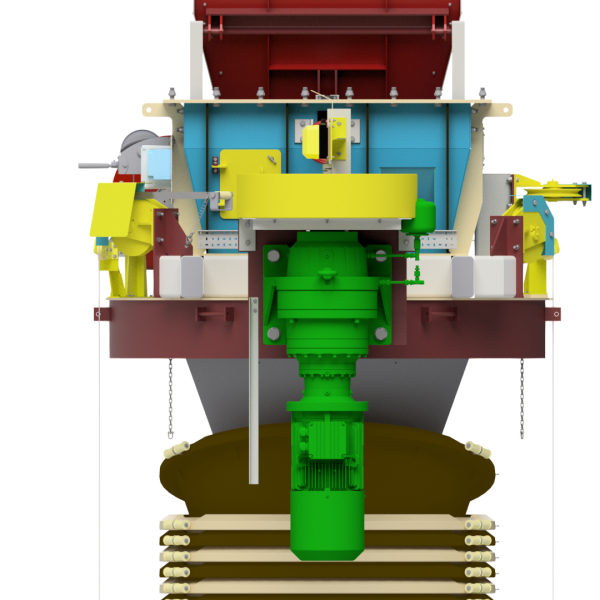

The rebuild process was as follows; installation of the cone stack into the carrier in the correct orientation alternating between the ‘A’ & ‘B’ cones as per the engineering drawing, attachment of the strops and new static earthing system to replace damaged/worn items, the refurbished shroud was then lifted over the carrier and placed onto the carrier flange, the carrier could then be lifted utilising the winch hoist ropes to be checked for balance, following this the carrier was raised with the strops and shroud to be attached at the head chute area in their respective locations, finally the outlet was reinstalled at the base of the system.

Phase 3 – Checks and Commissioning

All electrical and mechanical checks were carried out during this phase, most importantly ensuring that the control program follows the functions as advised by Cleveland Cascades in the control philosophy for safety and automation.

To end with, running trials were conducted both with the shroud down and then installed. It was witnessed that the system was performing to a high standard in both states, albeit that the throughput rate is lower than contracted.

Cleveland Cascades were advised that the throughput is unlikely to increase towards the higher contracted rate anytime soon. A note was made in the engineering report that should the rates increase, further trials are to be carried out monitoring the material through the cascade.

It’s of the utmost importance to Cleveland Cascades that all old, and future, systems provide our customers with the best possible results and aid with achieving minimal dust emissions and a better quality product through reduced material degradation. Please feel free to contact us on the below email for any product enquiries that you may have or to organise a site visit for system inspections.

enquiries@clevelandcascades.co.uk

See the gallery below containing photos from the trip.

- CC959 Carrier

- Cone Liners

- CC959 Cone Stack

- CC959 Shroud Replacement

- CC959 Static System Replacement

- CC959 ULS

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260