Cleveland Cascades to supply solutions for loading during times of inclement weather.

For our customers based in British Columbia, Canada, once any rain occurs on site, loading cannot be completed which halts operations. In order to combat this, our customer was advised that wet loading can take place through the use of a hatch charger outlet installed to their Cleveland Cascade system. These outlets are manufactured to suit the openings present on the cargo hatch of a vessel, a seal is formed once the hatch charger is inserted preventing water ingress to the bulk material being loaded.

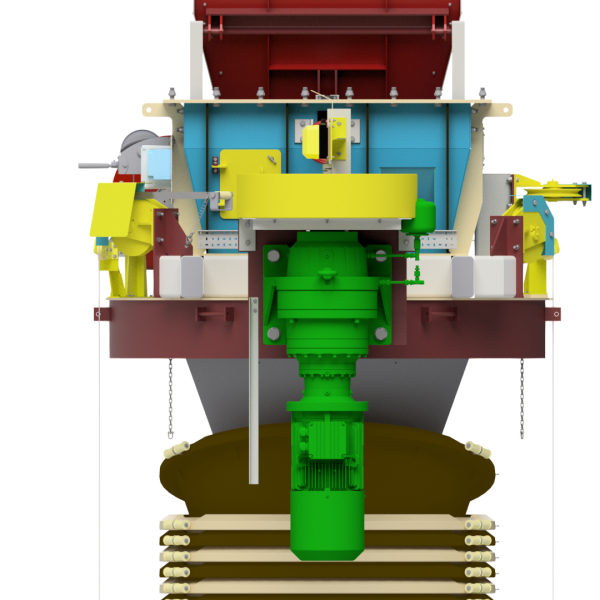

As the hatch charger is longer in length than the skirt outlet, one concern was the amount of clearance available to remove the system from a ship when in a retracted state. As a solution, Cleveland Cascades are to supply separate changeover spout sections with a reduced cone quantity and shorter extended length which creates more clearance once fully retracted.

For this solution to be viable, the amount of downtime between changeovers has to be minimal. There were several aspects to consider with the first being outlet changeover dependent upon weather conditions. A quick release interface is to be supplied installed to the carrier section of the spout which will allow for ease of removal/installation between the skirt and hatch charger outlet attachments.

Further consideration had to be given to the electrical connections as the existing setup on the system utilises a reeling drum hard-wired into a terminal box on the carrier for electrical distribution to the carrier section of the system. In order to allow for quick changeover, the design modifications will now incorporate a plug and socket system which will drastically reduce the time required to complete the changeover procedure.

Due to all of the additional equipment being supplied there was also necessity for storage/maintenance stands.

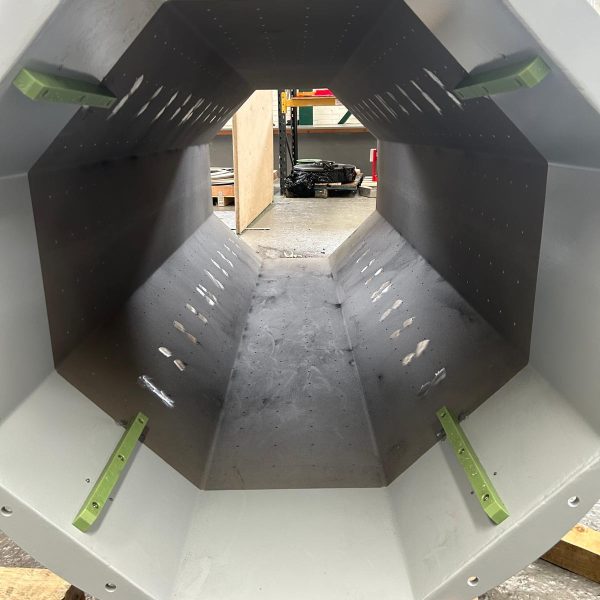

Please refer to the gallery of images below showing the equipment mentioned in the final stages of assembly. The completed installation and commissioning details will be featured in a future news story.

If you have any queries that you require assistance with, be it for a new or existing system, then please don’t hesitate to contact us at enquiries@clevelandcascades.co.uk

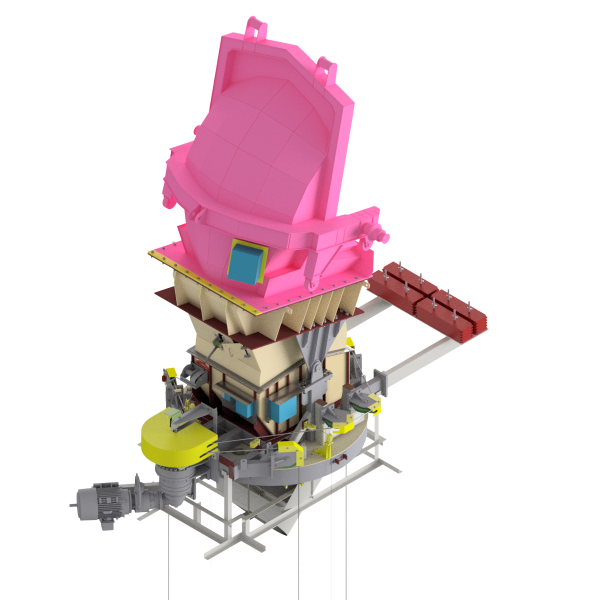

- CC930 Hatch Charger

- CC930 Hatch Charger Feed Spreader

- Skirt outlet and Shroud

- CC930 Carrier

- CC930 Hatch Charger Concept

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260