Cascade Chutes

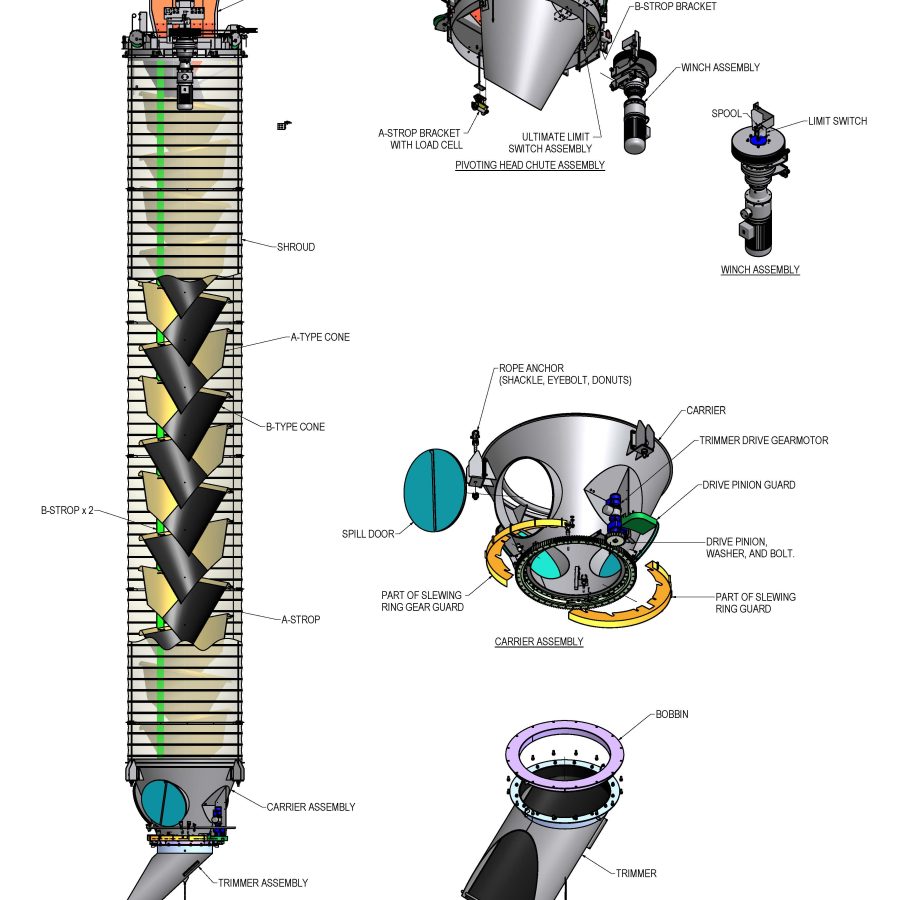

Utilising an innovative system of inclined cones, the Cascade system controls the descent of dry bulk material through the chute which largely eliminates dust emissions at source and minimises both product segregation and product degradation.

When material is allowed to free fall uncontrolled, it accelerates, and as the velocity increases dust particles within the material separate and are ejected by the fast moving air-stream created.

Ship loading represents a major challenge since the material must be delivered to the vessel’s hold from a boom conveyor, often at heights of 20 metres or more above the hold floor, generating high material velocity and extreme dust hazard.

The Cascade solution overcomes this problem by directing the material flow down a series of inclined cones, which limits the flow velocity to a controlled speed. The shape of the cone holds the dry bulk in such a way that prevents particulate separation and minimises material degradation. The significantly reduced product velocity creates a “mass flow”. A stream of material moving as a single mass through the chute and onto a stockpile with minimised segregation.

By using this technology, dust generation is practically eliminated at source, without the need for expensive, energy-intensive and high maintenance, dust extraction and filtration systems. The Cascade system can reduce dust emission levels to as low as 5mg/m3.

Materials handled

- Alumina

- Animal feed

- Bauxite

- Bentonite

- Biomass

- Cement clinker

- Cereals

- Coal

- Copper Concentrate

- Dolomite

- Finished cement

- Fly ash

- Grain

- Gypsum

- Iron Ore

- Kaoline

- Limestone

- Olivine sand

- Pelletized materials

- Perlite

- Petroleum coke

- Phosphate

- Polyhalite

- Potash

- Salt

- Soda Ash

- Sulphur

- Urea

- Zinc

Application

Ship Loading

Ship loaders face the challenge of achieving fast, high capacity loading, while at the same time minimising Dust pollution and preventing both material degradation & material segregation. The Cascade chute delivers on all of these key criteria.

Hundreds of ports around the world operate Cascade chutes to load a vast range of dry bulk cargoes. The Cascade design has established a global reputation for loading efficiency and performance.

Storage

Using the Cascade Chute to reduce dust emissions in silo & storage operations improves the working environment and reduces potentially dangerous dust accumulation in a confined area.

The Cleveland Cascade Chutes are installed in numerous silo & storage facilities across the globe loading a wide range of bulk products.

Biomass / Wood Pellet is a product which can be very dusty when loading. Biofuels are an important renewable energy source and the Cascade chute is ideally suited to loading high volume in a dust controlled environment.

The Cascade Chute enables controlled dry bulk transfer from the distribution conveyor system down to floor level effectively eliminating dust pollution, material degradation and segregation thus maintaining quality and improving the working environment.

Vehicle Loading Chutes – Cascade or Free Fall

Open Vehicle Loading Chutes

The loading of dry bulk material into open vehicles, whether road or rail, is an area of the industry which is susceptible to problems of dust creation, material degradation and separation as well as over-filling and spillages. Cleveland Cascade loading chutes can provide an effective high performance solution to meet all of these challenges.

Depending on the application and the material being handled we can offer our Cascade, controlled flow technology chute or our Free Fall vertical cone system. The cone material supplied can be agreed during the quotation process, but might include wear resistant liners and protection against corrosive materials such as Urea or Sulphur.

Chute Options

Steelwork & Cone Lining

Surfaces of the Chute which come in to contact with the loading material can be susceptible to abrasion or corrosion. In order to ensure a long service life, liners can be fitted to offset the worst effects of this wear. Liners can range from UHMW plastics, stainless steel and hardened steel to chromium carbide and ceramic tiles

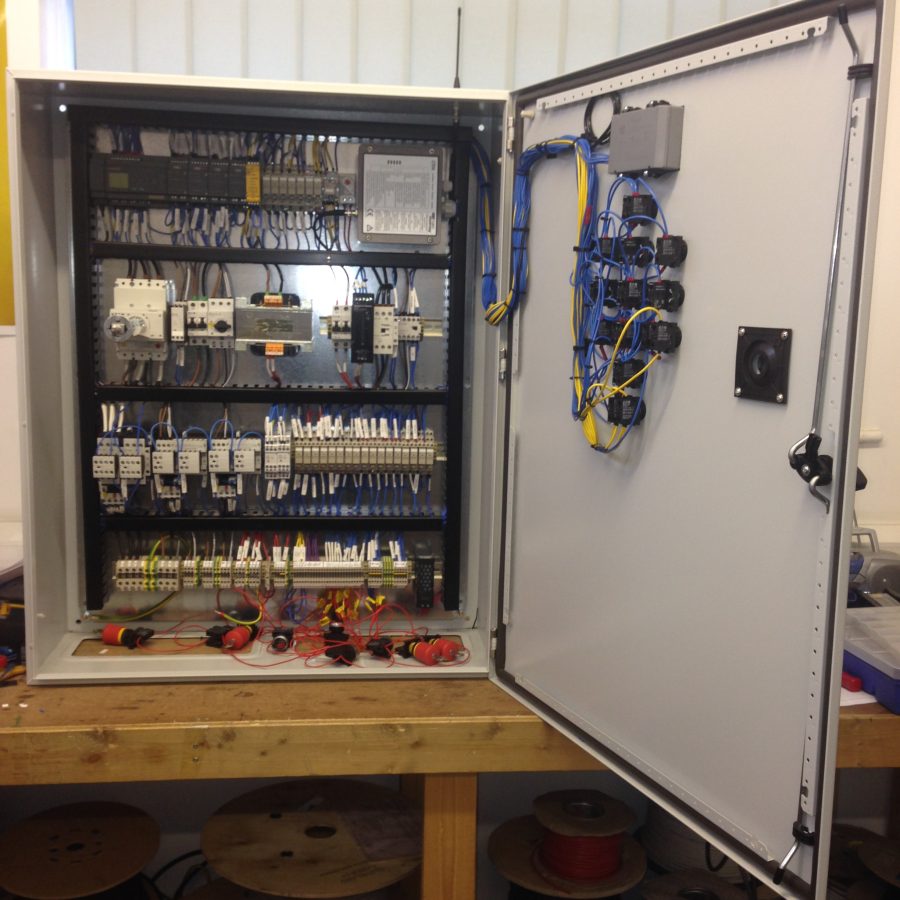

Controller Module

Cleveland Cascades Limited can provide the simplest operating systems through to extremely complex systems that can operate as part of a client’s loading operation. The control of the Cleveland Cascade chute can be seamlessly integrated to the client’s existing PLC equipment, or alternatively it can be independently provided and operated with a dedicated control panel and PLC as shown in the photograph below. As part of the control, Cleveland Cascades can also offer remote control systems and pendant stations for system operation.

These systems can range from the simplest of pendants to the more complex remote control stations incorporating a number of functions.

Resitain Valve

The Resitain Valve, is a trap-door type valve placed at the base of chute which is open during loading and closed when loading is complete. Its primary function is to prevent residual material falling from the chute when moving between hatches on a vessel or when moving back to the stowed position when loading is complete. The system is highly effective in eliminating material spills on the deck of the vessel or in to the water. It can help reduce the risk of pollution and reduce the need for post-loading clean-up operations.

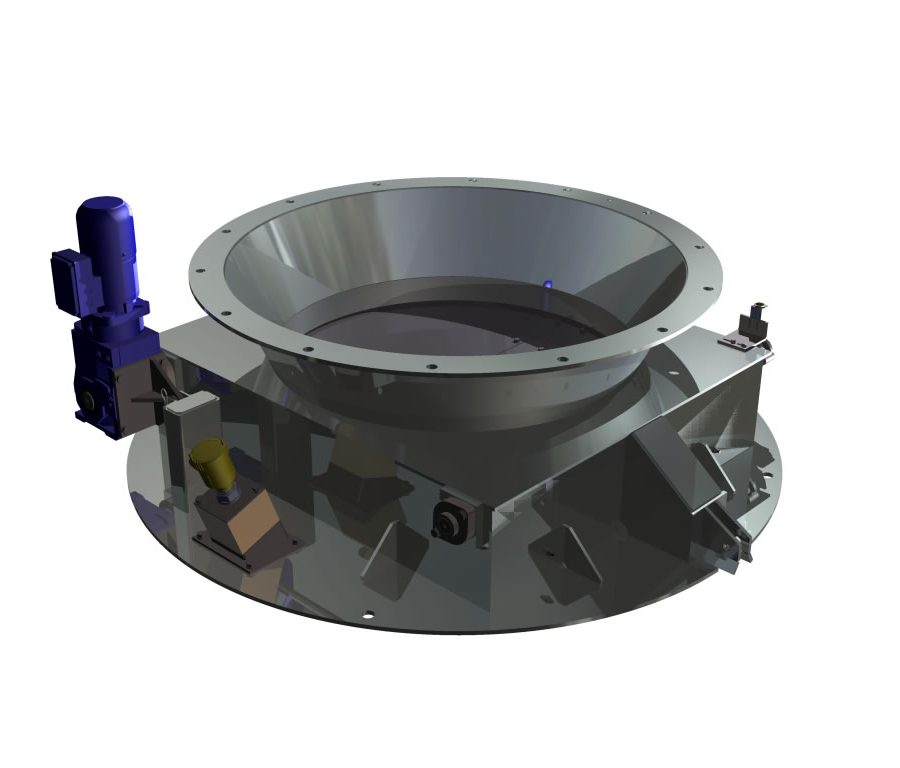

Rotating Trimming Spout

The Trimming Spout enables accurate positioning of the load within the ships hold and helps ensure maximum utilisation of the space available in the hold. The Trimming Spout is mounted to a slewing ring and has electric motor drive control. It can be operated either from the drivers cab or from a hand-held remote control device.

The Trimmer Spouts can be built from various grades of steel and lined with abrasion resistant liners for extended operating life. It can be installed permanently or can be detachable and used in addition to other types of removable outlet devices according to need.

Hatch Charger System

The Hatch Charger System has been developed by Cleveland Cascades for cement handlers, to overcome the problems associated with free-flowing materials which are sensitive to wet conditions. It is designed to accommodate any movement of the vessel or water during loading and enable continuous loading of closed “cement holes”.

Case Studies & References

We have built up an impressive population of Cascade chutes in loading installations all around the world, handling a wide range of dry bulk materials.

Here is a sample of companies who chose our Cascade, controlled flow technology chute.

- ADM Brasil

- Aughinish Alumina Ltd.

- Bedeschi SpA

- BRUKS Rockwood LLC

- Bunbury Port Authority

- Cargotec

- Cememti Rossi

- Cimbria Videbaek A/S

- Cleveland Potash Ltd.

- Conoco Phillips Ltd – Phillips 66 Ltd.

- CUCPSA

- Dead Sea Works

- Dublin Port Company

- Duro Felguera S.A

- EMS Tech Inc.

- FAM – Forderanlagen Magdeburg

- Fluor S.A – Alcoa

- Forth Ports Plc

- Inagromecanica

- Irish Cement Ltd.

- Koch Czech s.r.o

- MAN-TAKRAF fordertechnik GmbH

- Odebrecht

- PHB Weserhutte

- Port of Tyne

- QIT Fer Et Titaine Inc.

- Redland Aggregates Ltd

- Repsol Petroleo S.A.

- Rio Tinto Alcan Engineering Ltd.

- Samson Aumund Group

- Sandvik

- Seeger Industrial

- Telestack

- Tenova

- SMB GmbH

- South African Port Operations

And many more. Please see our Customer Reference List

Technical & Interface Data

System Integration

Cleveland Cascades offer a bespoke engineered solution to suit each specific site application and a crucial part of this is the interface between the on-site conveyor system and the chute. We offer design solutions which can be easily integrated into designs for existing or new loading systems, whilst also incorporating dedicated features to meet user’s special requirements.

In applications where Ships Air Draught is an important factor with larger vessels, we can offer a folding system which allows the retracted chute to be safely moved in to and out of the loading position, clear of ships sides.

Maintenance Access Platforms

Light-Weight Walkways

Where system access for maintenance is required, we can offer access decks and walkways. The bespoke design solution offered will take in to consideration the exact requirements of the user and can be constructed from a range of materials, including steel or GRP Fibreglass where the application is weight sensitive.

Technical Data

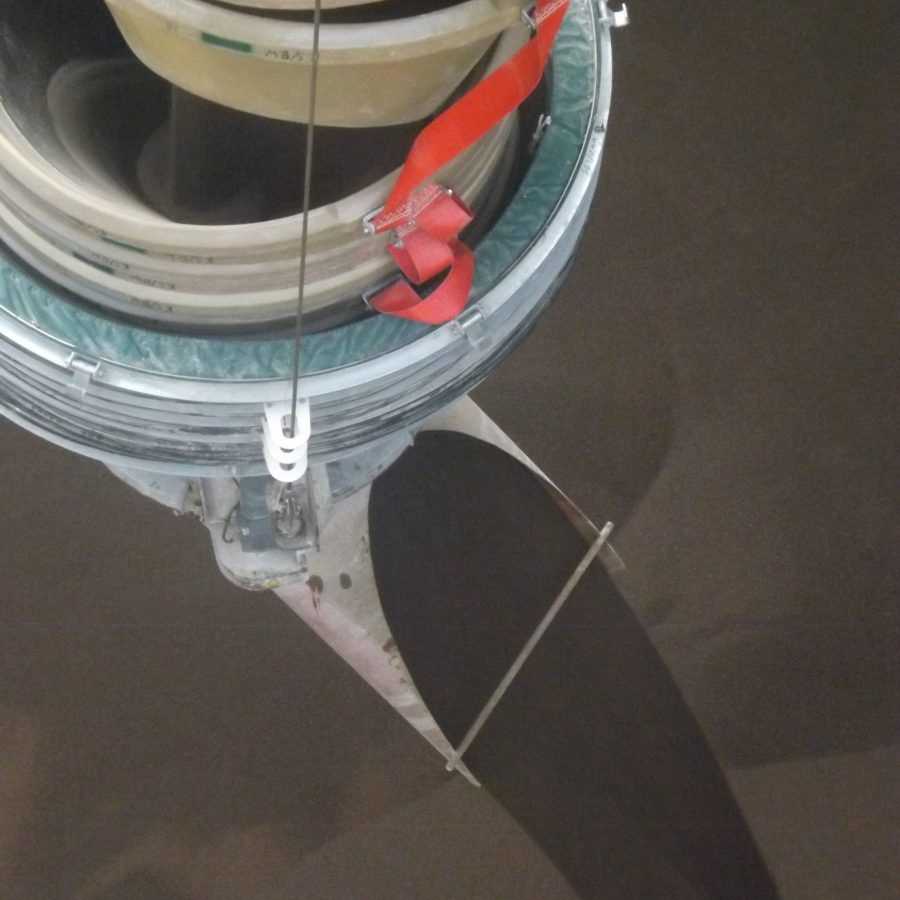

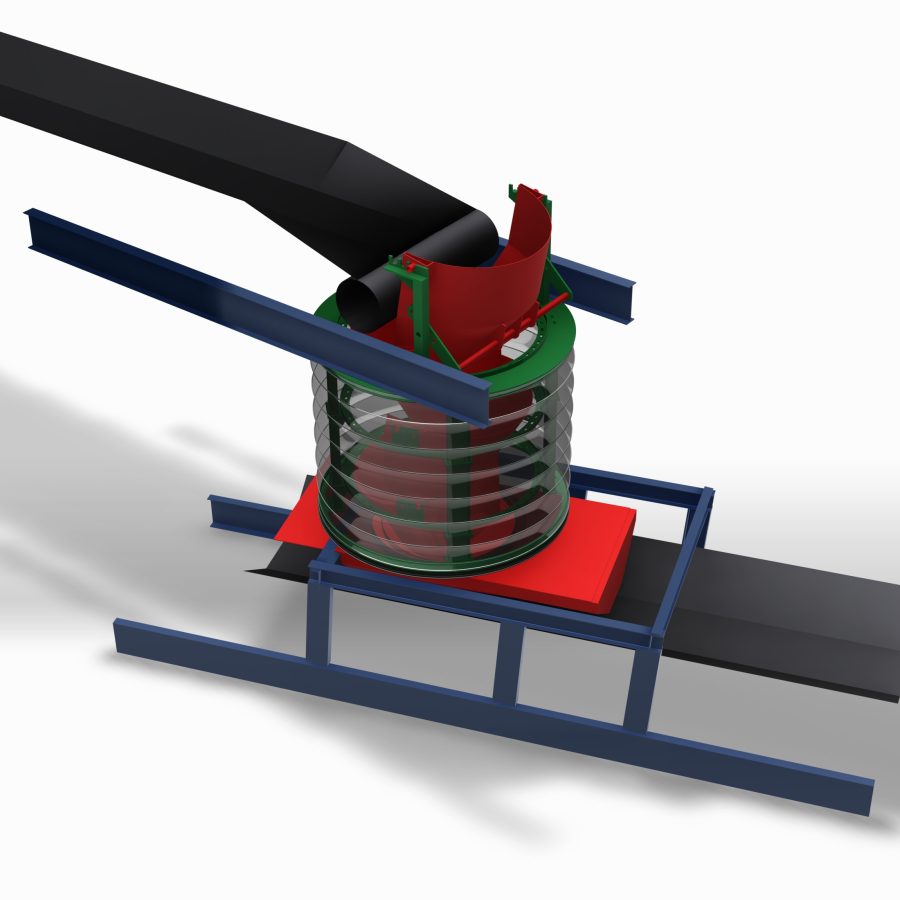

The Cascade chute has oppositely-inclined cones which are supported from flexible webbing-strops to control the cone angles. The optimum angle settings are calculated according to the material being loaded and the throughput rate. When not in use, or when the chute is maneuvered in to the loading position, the chute is retracted to the stowed position, with the cones stacked tightly inside one another.

Transfer Points

Transfer Points utilise Cascade, controlled flow technology in order to regulate the speed of material descent, between conveyors. They largely eliminate dust creation at source, as well as minimising both material segregation and degradation. This cost effective solution removes the need for expensive, high maintenance dust extraction systems.

Cleveland Cascades Transfer Chutes can be integrated into new or existing conveyor systems. The Cascade arrangement ensures that material is placed gently onto the receiving conveyor in the direction of travel, minimising impact damage, belt abrasion and reducing the need for impact sections.

The skirt-less delivery system further controls dust production and helps ensure material is placed uniformly on the belt, thus eliminating the need for skirting systems, which historically have been a major source of issues associated with belt tracking and ongoing maintenance costs.

Transfer Points often include skirts which can be susceptible to belt tracking issues and high maintenance costs. The Cleveland Cascade skirt-less design eliminates these problems and also further controls dust production and helps ensure material is placed uniformly on the belt.

Contact Us

Cleveland Cascades Ltd, Unit 22, Dukesway, Teesside Industrial Estate, Thornaby, Stockton-on-Tees, Cleveland, TS17 9LT, United Kingdom

Tel: +44 1642 753260